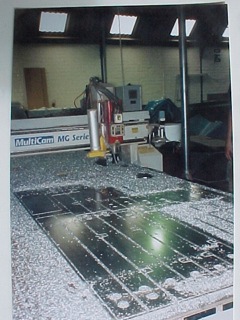

CNC Cutting the components with a router table

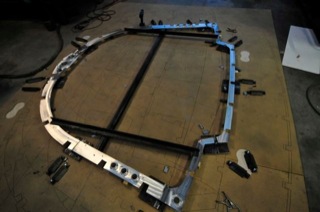

The pre-cut kit for Brian Russell of Odyssey Yachts

Follow construction of his yacht: http://www.odysseyyachts.com

Frame reinforcements for plumbing openings and lighting holes

Frame reinforcements welded in frame components

Weld preparation with back chipper

Frame weld

Assembled frame with stiffener for jig assembly

Forming the frame flanges

Fitting frame flanges

Frame flange tacked in place

Fitting bulkhead stiffeners and flanges

A water tight hatch fitted to a bulkhead

Setting up the frames on the building jig

All frames and bulkheads erected, stringers installed

Steel and aluminium boats are shown

Preparing the tanks and tank lids

Installing the tanks and keel structure. Note how all the limber and drain holes as well as through-weld openings are included in the kit

C&J Boat Builders in Cape Town rolling the keel sides

Keel leading edge fitted. The slotted centre line stringer ensures a very accurate fit

Hull Bottom plating installed

The position of each frame is marked on the hull plating to ensure accurate construction

Fitting the topsides

Exact height of plating marked on frames, exact location of frame marked on hull plating

Radius chine plating fitted and tacked in place

Radius chine plating welded from inside

Hull welded inside and outside. Note how the final outer weld induces compound curvature.

Turning the hull

Fitting the cockpit (left: PH steel, right: HD alu)

Note the accurate, clean work. All bending lines are included in our files

Landings included in cutting files saves many ours of labour

Coach roof and deck fitted

Preparing the window frames

A Dix 43 HD built by Nereide Yachting

Customised details on a Dix 43 HD

The Dix 43’ pilothouse, our best selling design of this size

This hull was built by Peter Randle Yachts. It is the first steel yacht they had ever built. The excellent results are proof that a professionally engineered kit will save money and result in a very high degree of accuracy and hull fairness.